The engine fell off the UPS cargo plane, but that’s not the sole reason it crashed

Opinion

November 6, 2025 — 6.23pm

November 6, 2025 — 6.23pm

When an aircraft crashes as tragically and spectacularly as UPS 2976 did on take-off from Louisville, Kentucky, it’s normal to search for the cause as soon as possible. And while it’s irresponsible to speculate, what we know for certain is that the 34-year-old MD11 was bound for Honolulu, a distance of just over 7000 kilometres and a flight time of around nine hours, so the aircraft would have had a heavy fuel load.

The McDonnell Douglas MD11 is the last iteration of the Douglas DC10, which entered service as a passenger aircraft back in the 1970s. Although no longer in production, the DC10/MD11 family of aircraft has had a chequered career in both airline passenger service and air freight.

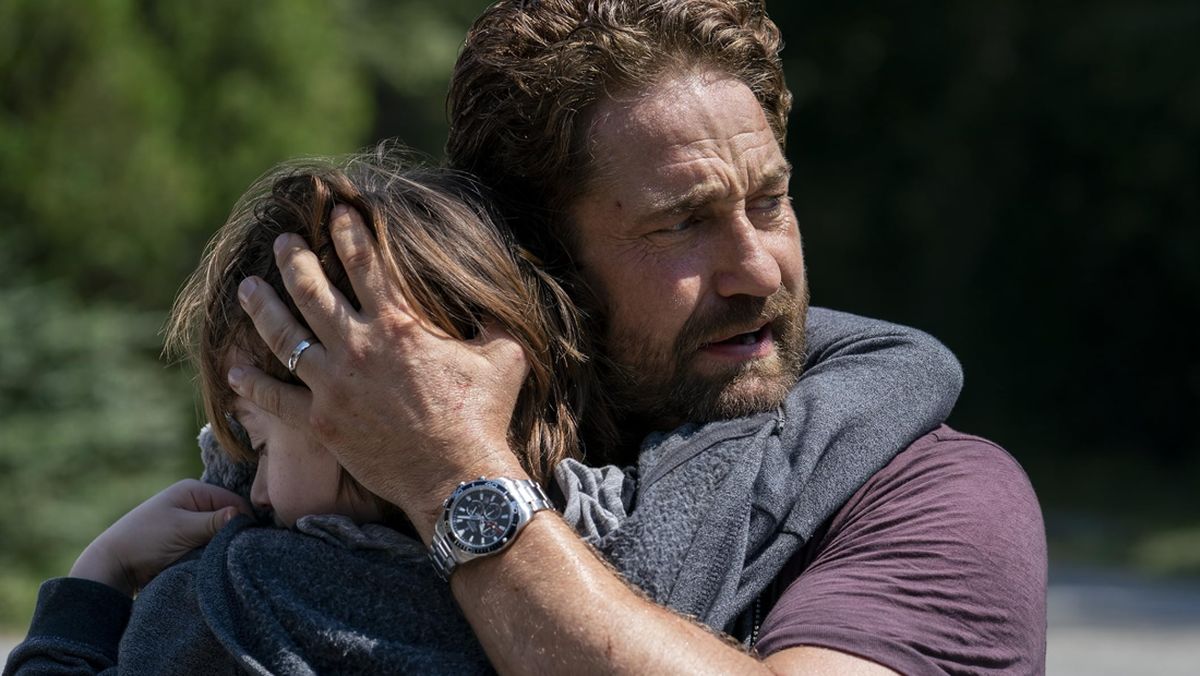

Credit: Nine News

In 1974, a cargo door on a Turkish Airlines plane burst open mid-flight, resulting in the deaths of 335 people; in 1979, a left engine separated from an American Airlines flight during take-off, killing 273, and many will recall the tragic loss the same year of Air New Zealand’s DC10 into Mount Erebus on an Antarctic flight, although that was not a fault of the aircraft.

Since then, many design flaws have been rectified, but the aircraft’s reputation had suffered as a result and all remaining MD-11s were converted to freighters and ply their trade as cargo-only planes.

This latest tragedy has taken the lives of the three crew members and up to 11 people on the ground, although those numbers may change. The Aviation Herald is reporting the aircraft was delayed on the ground for up to two hours while work was carried out on the number one engine – the engine on the left wing that video evidence shows engulfed in flames during take-off and separating from the aircraft during the attempt to become airborne.

Loading

An engine physically separating from the aircraft, although extremely rare, is a design feature of all modern aircraft with engines slung under wings. They are attached to the wing with “fuse” pins that are engineered to fail and protect the wing structure if something catastrophic happens to an engine running at high power, such as during take-off.

Data shows the aircraft achieving around 185kts, around 340 km/h, which is a typical rotation (take-off) speed for this type of flight. Take-off and landing are the most critical time of any flight and where the safety margins are thinnest. These safety margins are analysed, with the risks mitigated on all flights by the pilots calculating a number of critical speeds. These speeds vary for each flight and are dependent on the environmental conditions such as temperature, atmospheric pressure, wind speed and direction, as well as the actual aircraft weight. The speeds are known as V1, VR and V2.

V1 is the speed at which the aircraft can accelerate on the runway and subsequently abort the take-off and stop on the remaining runway – in other words, the “point of no return” beyond which, if the take-off is aborted, the aircraft will not stop be able to stop on the remaining runway.

VR is the rotation speed where the pilot lifts the nose of the aircraft skywards and allows the wings to generate enough lift to take the plane safely to the sky.

Loading

V2 is the next critical speed, where it is assumed that an engine has failed at V1 and the aircraft continues accelerating down the runway with the remaining engine/s still producing take-off power. This V2 must be achieved as it is the most efficient speed to fly and achieve the necessary climb profile to avoid hitting anything in the take-off path.

If it sounds complicated that’s because it is, so the piloting skills to achieve all the calculations and manipulative skills are tested twice a year – known as a V1 cut.

Pilots must be able to demonstrate their ability to fly a multi-engine aircraft with one engine “failed” at V1. Imagine the asymmetric forces at play with all the power coming from one side of the aircraft. You have to manually fly the aircraft into the air and accurately maintain V2 all the way up to a safe altitude.

The pilots of UPS 2976 certainly did demonstrate this skill. Data shows the aircraft accurately tracking down the runway centreline after the engine failure, with all the subsequent asymmetric forces well after V1.

Clearly, something else has come into play, whether that’s debris from the failed engine affecting other systems, or power plants leaving the pilots with insufficient aircraft performance to achieve V2 and safe flight.

The investigation into this tragedy will be thorough, and the aviation industry will learn and make what is the safest form of travel even safer in the aftermath.

David Evans was a Qantas pilot for 37 years.

Start the day with a summary of the day’s most important and interesting stories, analysis and insights. Sign up for our Morning Edition newsletter.

Most Viewed in World

Loading