Imagine a plastic container, bobbing on the ocean. It could take thousands of years to break down, although it would never truly disappear – leaving millions of pieces of microplastics and nanoplastics in its wake.

But what if you could add enzymes to plastic before it’s formed into a container, which would break down the plastic after use – as quickly as a matter of weeks – and even faster in salt water?

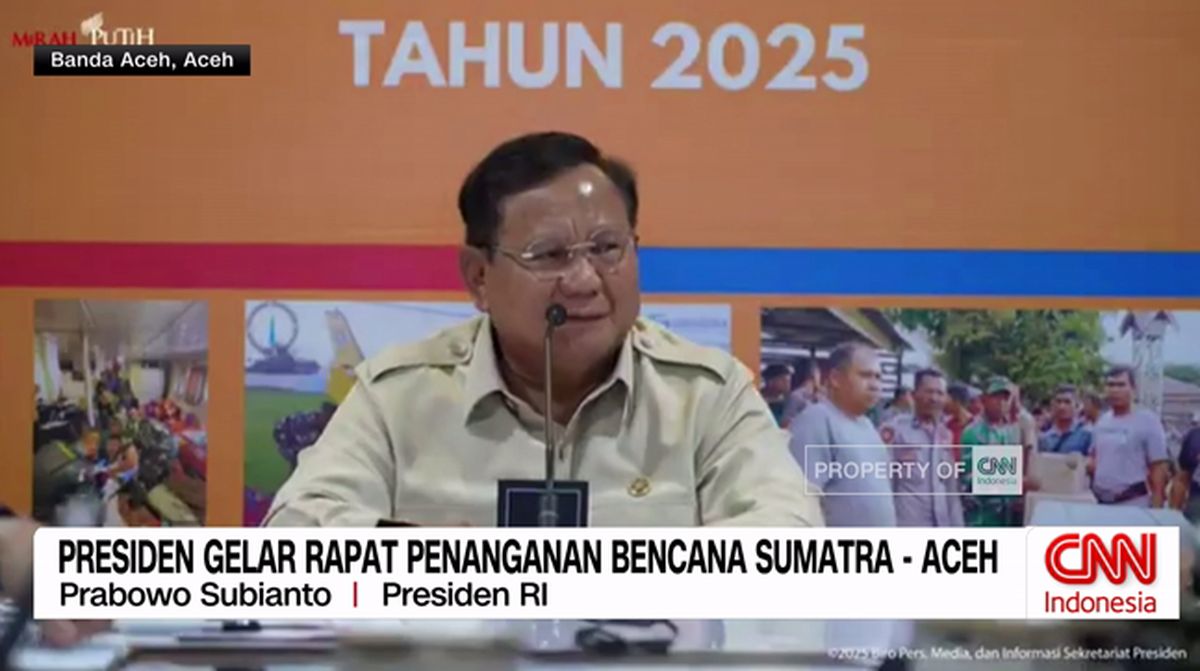

The most divisive issues include capping production, managing plastic products and chemicals of concern, and financing to help developing countries implement the treaty.Credit: Istock

Scientists have spent six years testing super enzymes which – when added to bioplastics – could mean discarded plastic can safely return to the environment after its use, without breaking down into microplastics.

They now believe the technology can be market ready within 12 months.

Loading

Plastics chemist Dr Pete Cass began working on the innovation at CSIRO before leaving to join private company Enzide, which is developing the technology.

Cass said enzymes were naturally occurring proteins that broke down plastics.

“But most of them aren’t ideally designed for that plastic; they chew upon plastic slowly,” he said.

“So what we’ve done is we’ve sourced an enzyme that has a really, really good attraction and is really capable of hydrolysing the plastic.”

The enzyme is implanted in biodegradable plastic as it’s formed, and activates when it is exposed to moisture – either in compost, landfill or water bodies.

For this reason, its application for use in drink bottles is still under development, but the team is preparing to take fully compostable plastic packaging and agriculture packaging to market.

Not fantastic plastic: more and more fruit and vegetables are being sold wrapped in plastic.Credit: Jessica Hromas

Enzide chief commercial officer Richard Newton said the majority of innovation in plastics was in “downstream” solutions to plastic waste, rather than upstream solutions.

“We’re [working on] getting the fix in the product when it’s manufactured. That just seems logical to us ... relying on human behaviour and relying on people to do the right thing with their waste – we know it doesn’t work because of the pollution problem, so why not try and get a fix inside when you’re manufacturing the product.”

Loading

He said the enzyme-charged biodegradable plastic would only cost a small amount more than regular, fossil-fuel generated plastic.

As plastic ages, it degrades into microplastics, small pieces of plastic smaller than 5 millimetres, and nanoplastics, which are invisible to the naked eye but enter the air, water supplies and the food chain.

The Australian Packaging Covenant Organisation (APCO), representing the packaging industry, estimates Australians used 1.26 million tonnes of plastic packaging in 2022-23 – equivalent to 47 kilograms of plastic packaging for every person.

Up to 98 per cent of plastic that is reused is “down-cycled” in lower-grade products like road bases, which continue to degrade into the environment and atmosphere.

The enzyme-charged biodegradable plastics project is one of 11 this year to secure investment from Minderoo Foundation, the charity launched by Andrew and Nicola Forrest in 2001.

The organisation runs a $250 million strategic impact fund that invests in companies and initiatives that have the promise to deliver scalable and systems-level solutions to global challenges.

Unlike other investors, the fund considers the potential impact of the project being funded, as well as the risk-adjusted returns it could deliver.

Another is Kalpana Systems, a Dutch start-up that has created machines capable of producing ultra-thin aluminium coatings, 5000-times thinner than human hair. In this way, according to a Minderoo spokesman, they can transform recyclable paper into a water, oxygen and greaseproof replacement for plastic.

Minderoo chief executive John Hartman said the backing showed the power of investment capital.

“These investments go against the trend when you consider 82 per cent of financing in plastic innovation focuses on downstream improvements rather than upstream design,” he said.

Get to the heart of what’s happening with climate change and the environment. Sign up for our fortnightly Environment newsletter.

Most Viewed in Environment

Loading