It was in the middle of May that Adam Gilmour began to worry that he would not, in fact, live in a city on the moon after all.

Gilmour was standing inside mission control – a dark demountable filled with computers and cords and screens – monitoring the third attempted launch of his expensive, obstinate rocket, seven kilometres away on the coast of Bowen, gleaming brilliant white in the tropical Queensland sun, and refusing to budge.

This rocket is named Eris, and names mean a lot to Gilmour. His own children bear those of Star Wars heroes: Ben, Leia and Allana. Eris is the name of a dwarf planet orbiting at the edge of our solar system, a place Gilmour says he would like to voyage to one day, and therefore a symbol of his soaring, galactic ambition. Unfortunately, Eris is also the Greek goddess of strife, and the rocket was beginning to embody the name of that deity, stranded on the launch site for 17 months, rusting in the salt spray off the nearby coastline. The only thing on fire was money, both Gilmour’s and his investors’: $4 million a month, every month for more than a year, his eponymous company having so far spent almost $200 million on the project.

It’s been a journey. Gilmour Space Technologies has endured not just stubborn and sometimes nose-diving rockets but fights with regulators, bad weather and crummy parts suppliers, to be right here, on the precipice of something completely new. Eris, you see, is powered by a revolutionary type of engine that has never before reached orbit (more on that later). A successful launch could put Gilmour, 51, on a potential path to challenging billionaire Elon Musk’s SpaceX, while also whetting the appetites of generals looking for superfast war machines – not to mention proving that an amateur rocketman can get to orbit through sheer force of will.

Eris is a temperamental piece of machinery – requiring Gilmour’s engineers to scurry across her length, solving finicky problems before each take-off – and she will ascend only into the most gentle of breezes, both at ground level and high in the atmosphere. As Eris pointed skywards on her erector, chasing that landmark launch, the weather was finally, thankfully, calm. That’s when an electrical fault caused the rocket’s nose cone, or fairing, to fall off. (Note: this is a fairly significant problem, given the fairing is designed to carry a rocket’s payload into orbit, then hinge itself open, revealing its pearl: usually a satellite, which is gently pushed away into space.)

“It was never-ending, and every month another $4 million was burning,” bemoans Gilmour, who is wiry with sun-bleached red-blond hair, and often speaks with the excited urgency of a person being electrocuted. “I remember being really, really blue.”

Adam Gilmour, co-founder & CEO at Gilmour Space Technologies south of Brisbane.Credit: Paul Harris

So began the interminable wait for yet another launch window. After all, you can’t just shoot a jet-powered hunk of steel into the sky whenever you want – the Civil Aviation Safety Authority needs to clear a huge geographical area around the launch pad, so that unsuspecting fishermen or kite-surfers don’t get hit with an errant fuselage. All of which is how we get to the final desperate promise of July, with Gilmour granted a fourth launch window of a few days.

“Six days out, you’re already up there, you’re already charging the batteries for the rocket, it’s almost about to roll out, and then you see the winds, and the winds suck,” says Gilmour. “And you’re like … ‘Shit.’ ”

The winds are too high on the first day. Too high on the second day. And on the third. Day four dawns hot and sticky but mercifully calm, so the rocket is fitted with its ceremonial payload. Musk once shot a Tesla Roadster into space. The cargo on board Eris? A single jar of Vegemite.

Rockets are, of course, precision-engineered to the micrometre, so Gilmour controls every factor and variable until the final couple of minutes of the countdown. Then the rocket itself has control. It monitors its own systems, checks its telemetry, tests the winds and makes its own final decision to launch.

At 8.29am on July 29, Eris initiates “autosequence” – what we non-rocketeers call a countdown – 10, 9, 8 … – and Gilmour stares at his screen.

“The stakes were super high,” he says now. “We’d been delayed. And there was a risk we wouldn’t get any follow-up funds if we couldn’t get off the pad. It was do-or-die for me. We had to get off the pad.”

As a national science writer, I’ve been covering Gilmour and Australia’s fast-growing space industry for a handful of years, without much cut-through. But launching an actual rocket? That tends to sharpen the attention of newspaper editors, particularly when viral-albeit-shaky footage emerges.

Gilmour’s launchpad on Queensland’s eastern edge is at the top of the Whitsundays, where beaches are fringed in shallow reefs and holidaymakers come to snorkel, sunbathe and bite into the fat gold flesh of the mangoes for which the area is known. Otherwise, Bowen is pretty flat. The only real raised spot is “Mount” Nutt, which is 43 metres above sea level – higher if you count the big concrete water tank where locals gathered to watch the show. That’s where Josh Keegan, a rocket enthusiast who goes by the online moniker “Aussienaut”, had set up his livestream.

Keegan had been up there for hours on that day in July. Eris had missed her 8.33am launch time by one minute and it looked like another scrub, which is why you can hear a resigned sigh from Keegan in the footage. He remembers briefly turning away to deal with a technical issue, which is when the rocket finally moves, wobbling just a little. In his footage, clouds of white gas rise up above the tree line. A shout goes up from the crowd and Keegan spins back, training the camera on the rocket in time to show Eris floating, just above the tree-tops, then suddenly sliding right amid puffs of manoeuvring thrust.

“It’s hovering! It’s hovering! It’s hovering!” he shouts, somewhat hopefully, despite clear evidence that the rocket is now actually falling, falling, falling. Finally the 23-metre, 30-tonne projectile disappears below the treeline. “It’s … gone! It’s gone!” Keegan yells. “Oh no! It did not go ...”

But it almost did go, which is why I find myself now driving up the Pacific Motorway past the Gold Coast’s roller-coaster whorls to the rocket factory of Gilmour Space. From phone interviews, I had pegged Gilmour as a loudmouth entrepreneur – a brash guy making constant demands for more government funding while repeatedly missing launch windows. He has promised (and failed) to reach orbit in each of 2020, 2022, 2023 and 2024. “He is very loud. You want him to succeed,” one space industry insider told me. “But I don’t hate it that he blew up.”

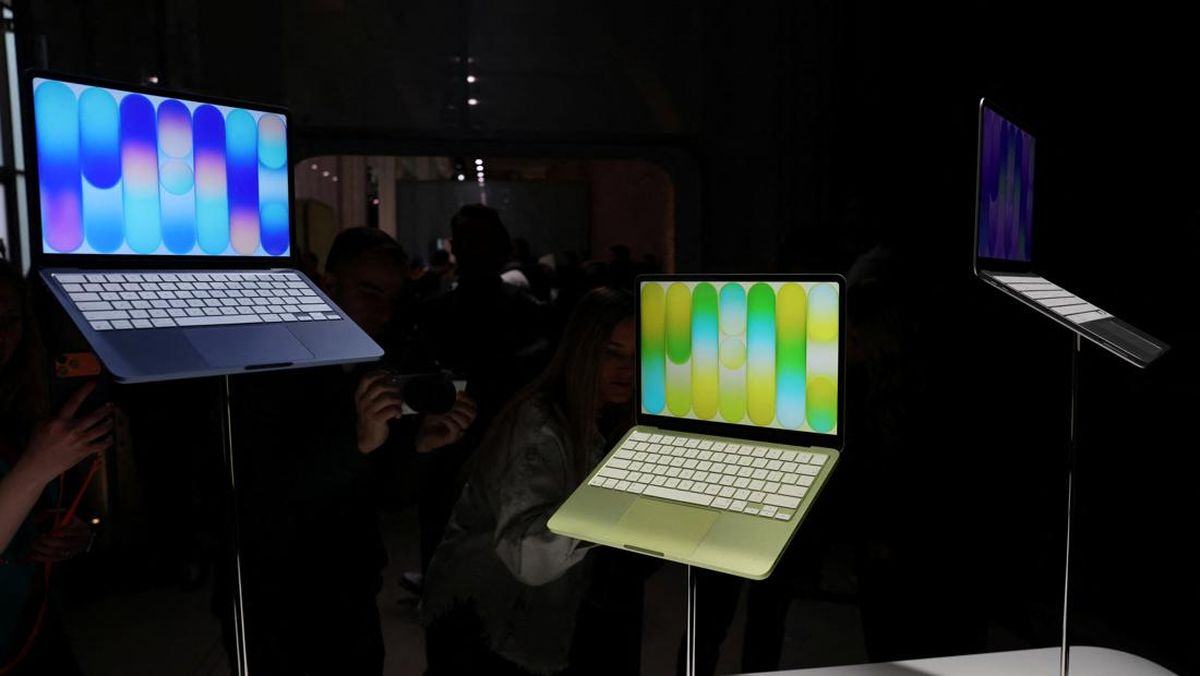

while Eris failed to launch in July, it did clear the pad, keeping the funds flowing to Gilmour Space as engineers continue to troubleshoot remaining issues.Credit: Gilmour Space Technologies

In person, the Adam Gilmour experience is different. The fervour is real, and personal. “I think we’re going to have bases, permanent cities on the moon. And I’d like to have one of them,” he tells me. And I believe him – or, at least, I believe he believes.

Gilmour was born in Brisbane in 1973, the second of Brian and Dierdre’s four children. Gilmour and his younger brother James were close to their grandfather Ken, a fitter and turner and amateur astronomer, who filled his house with home-made telescopes and star maps. “He used to take me on top of the roof of the house he built with his bare hands,” says James. “He showed me the constellations.”

‘I think we’re going to have bases, permanent cities on the moon. And I’d like to have one of them.’

Adam GilmourFrom Dierdre, who now has Alzheimer’s, came the blessing of limitless self-belief. “She taught every child that there was no ceiling at all, always possibilities,” says Brian. “It’s pretty sad she does not know what they are doing.” But he adds she would be impossibly proud of them, as he is. “I haven’t got any shadow of a doubt,” he says. “They will land on the moon.”

This disposition for doubtlessness seems strongest in Gilmour. “I can build anything; anything that has been built by human beings, I can build it,” he says. “I could build a nuclear submarine. I don’t want to, though – I’m pretty happy building rockets.”

Building nuclear subs and revolutionary rockets and moon bases … It seems crazy, right? It is crazy. But Gilmour says crazy things with such absolute white-knuckle conviction that the people around him start to believe him, too. “Everyone in this industry is a bit crazy,” says Jamie Anderson, the company’s former head of propulsion. “I looked at him when he offered me the job and thought: ‘You are crazy enough to do this.’ ”

As kids, Gilmour and his brother James watched Star Trek and Star Wars, and James would flick through The Young Scientist Book of Spaceflight. He’s still got a dog-eared copy, which will go in another thing the brothers plan to build one day: a spaceflight museum.

First, they had to make their way in the world. Gilmour went into banking – trading currencies and later derivatives for Citibank, eventually rising to the managing director’s office in Singapore. James, meanwhile, became a salesman and then a business manager at Dell. Then the global financial crisis struck in 2007. Citibank needed a huge government bailout and its appetite for risk then contracted. Around the same time, an exciting new pool of risk was opening: entrepreneurial spaceflight.

The Apollo 11 mission that put Neil Armstrong on the moon was calculated to have cost $US2.9 billion in 2020 dollars. In 2004, SpaceShipOne became the first privately funded crewed vehicle to reach space – at a cost of about $US25 million. At home on his parents’ farm on the Hawkesbury River in Brooklyn, NSW in 2011, Gilmour brought an idea to the dinner table.

“He originally pitched the idea to build a spaceplane. And a space-education initiative,” says James. “I wouldn’t say there was always a dream or a goal to start a rocket company.” Dierdre told James he should join the company as well, and when Adam asked, he said yes straight away. “I always knew,” James says. “We wanted to do something special.”

Gilmour Space’s early years were nebulous and unsettled. There was a plan for a space theme park and astronaut training facility – complete with a Mars mock-up – at a strawberry farm the brothers bought on the Gold Coast. Then they thought they might build satellite components in Singapore. When they approached launch companies to test their components on an orbital flight, they were quoted $US8 million for a 20-kilogram test launch. “I thought that was insane, and such a lousy price it would stifle the industry,” says Gilmour. “And I started thinking: ‘these launch providers have got the market.’ ”

‘I could build a nuclear submarine. I don’t want to, though – I’m pretty happy building rockets.’

Adam GilmourThat might make Gilmour sound mercantile, but he’s actually the dreamer. Literally. In high school he even won the Biggest Dreamer award. It’s James who brings the attention to detail, and now runs the launch operation in Bowen, and Michelle, Gilmour’s wife, who helps the brothers’ partnership and the company work. As Gilmour Space’s manager of communications, she’s self-deprecating, insisting she knows little about rockets while explaining every detail of the factory. Space, however, is not her passion. “I did it for Adam,” she says. “I said, ‘Look, you earn more money than I do, I’ll quit first, and I’ll help where I can.’ ”

“It gives us a lot to talk about,” says Gilmour, when I ask about running a company with his spouse. “I think it’s good for me to see her pain, for her to see my pain, and understand it.”

From left: James Gilmour, co-founder and head of Launch Site Operations with Liana Gilmour (James’ partner) and Adam Gilmour, co-founder & CEO, and Michelle Gilmour, manager of communications at Gilmour Space Technologies.Credit: Paul Harris

Elon Musk started SpaceX by reading books and academic papers on rockets. Unprompted, Gilmour tells me his story “is a little bit like Elon’s”. He, too, started with books and papers he’d download from NASA’s website. He explored buying off-the-shelf rocket parts but decided it would be cheaper to just develop his own. One key difference was their technology of choice: Gilmour had become fascinated by a promising but untried Soviet rocket design – the hybrid.

The modern “big rocket” basically comes in two varieties. Solid-fuel rockets, like the Space Shuttle’s boosters, are essentially slow-burning sticks of dynamite with a nozzle on the bottom. Liquid-fuelled rockets, such as SpaceX’s Falcon, use complex and expensive engineering to mix and ignite fuel and oxygen in a much more powerful explosion.

Loading

Hybrids combine a solid fuel and a liquid oxidiser. In theory, they are cheaper and simpler to build than liquid-fuel rockets, more powerful than solid-fuel rockets, and much less likely to explode than either. “This is why people say it is the holy grail of rocketry,” says Jamie Anderson. “You can effectively start a rocket program from a light industrial shed in the middle of the suburbs.”

But hybrids pose a key technical challenge: the fuel burns too slowly. You don’t get enough thrust. No hybrid has ever achieved orbit. An American company managed to get a hybrid rocket off the pad in 1984 – and then collapsed into bankruptcy.

Yet among hobby rocketeers, hybrids have become the engine of choice because they are simple and safe. They’re less likely to blow up, hence no fireball in that vision from the day Eris crashed. Those rocketeers were an untapped pool of engineering talent, who loved space enough that they’d uproot their lives to work for someone who promised a chance at dream fulfilment. Gilmour hired some of them, and they developed a new type of quick-burning fuel and special injector, and started testing rockets in the paddocks of Gilmour’s parents’ then farm. They worked their way up from hobby rockets to upper-atmosphere test rockets (successful) then to a nine-metre rocket (unsuccessful; cartwheeled off the pad and landed nose down) and finally to Eris (the relative success or failure of which is a matter of some debate).

Eris’s July test-flight stumble was attributed to the failure of its hybrid engines, with the data suggesting the turbo pumps – that push oxidiser over the fuel grain – were drawing too much power and shut down. The fix is simple enough even though the root cause is not yet obvious, says Gilmour, who thinks the 17-month wait on the launch pad contributed. “This was an old clunker.”

The take-off is the hardest part of any launch. SpaceX’s first three rockets failed. Eris’s 14 seconds of flight time – and with the company’s guidance computers and launch infrastructure both working – mean about 50 per cent of the rocket is now flight-tested, which is why Gilmour called it a “strong result and a major step forward”. In the control room on the day itself, he was ecstatic. “As soon as we left the pad,” he says, “the company was saved.”

Not everyone agrees. A week later, in a not-so-subtle dig, Peter Beck, the CEO of New Zealand competitor Rocket Lab, told investors, “You’re not gonna hear some rubbish about just clearing the pad as a success.”

Despite admitting to some missteps, Gilmour is keen to slate maximum blame for scheduling to the Australian Space Agency (ASA), which he castigates as a bunch of risk-allergic bureaucrats. I put this to the head of the agency, Enrico Palermo, who responds by pointing out that the schedule isn’t determined solely by the regulator, but also the timely manner and nature of the information they receive from rocket companies.

Gilmour isn’t having any of it, still clearly annoyed by the refusal to green-light his launches for months on end. “When you don’t know anything you just suspect everything,” he says of the ASA. “You have a greater risk of getting hit by a meteorite than by our goddamn rocket. It was just insane.”

Adam Gilmour with Eris, which is 23 metres from tip to tail and is made of aluminium – light, cheap, easy to work with and to mass-produce.

Back in 2019, a CNET journalist visited Gilmour Space, then inside a repurposed roadside cafe, with engineering staff working around old kitchen appliances. How things have changed. It’s now a sprawling custom-built warehouse, paid for with about $50 million of private and taxpayer money. When I visit, most of the 230-odd employees have the week off to recover from the stress of the launch campaign, but the place still buzzes. 3D printers fabricate rocket parts out of plastic and an alloy developed for spaceflight. Machines to print circuit boards have just been installed. Oliwia Andrejko, who emigrated with her husband from Poland to work for Gilmour – one of many international transplants called by the rocket’s siren song – shows me the first green-grid circuit boards, which roll off the fabricator like warm toast out of a hotel buffet’s toaster. Solar cells are manufactured over here, lithium-ion batteries over there. Several technicians seem to be spit-roasting a large piece of black plastic over a fire – a process I am not allowed to know about.

I keep walking, and suddenly there it is – Eris. Laid out horizontally, in enormous stages, like the metallic skeleton of a blue whale. I’ve written about satellites and deep-space radar dishes and missions to far-off asteroids, but there is something emotionally resonant about seeing a vessel built to punch through the atmosphere. Gilmour knows how I feel. “The ground shakes, the air hits you in the chest,” he recently told a podcast. “It’s almost like you’re feeling the force of God.”

Eris is 23 metres tip to tail. Gilmour chose to build it out of aluminium because it’s light, cheap and easy to work with. That’s a mantra at the company, too, because for Gilmour to truly succeed, there can’t just be one launch. They have to achieve mass-production. Eris has to be the Model-T of rockets: you can have any colour you want so long as it reaches orbit.

“I’m on the hook for multiple rockets per annum. I won’t give you the number, it is scary, but we can definitely do it,” says head of production Matthew Halstead. As a sign of this ambition, in the centre of the warehouse, ample room has been reserved next to Eris for another rocket assembly line, maybe even three more.

Gilmour could buy in custom-fabricated metal components for the rocket’s skeleton, but says it’s actually much cheaper to buy and process cheap sheets of aluminium themselves. “One day we hope to have sheets of metal come in one end,” says Michelle, “and the rocket go out the other.”

Eris is almost ready for its next launch. Its silver bones will soon be painted with a special white ablative paint that will smoulder and fall away, dissipating heat as the rocket burns through the atmosphere. Early next year, hopefully, engineers will truck it out to Bowen, and point its tip to the sky.

Spaceflight is an extremely effective way of separating the rich from their fortunes. Richard Branson’s companies blew up an orbiter, killing a pilot, and then went bankrupt. SpaceX was literally built on the ruins of Beal Aerospace, shuttered in 2000 despite a successful test-fire and the backing of a billionaire. Gilmour has spent about $5 million to self-fund Gilmour Space (“I was well paid – and a really good saver”), and James has invested, too. So far, the company has raised about $143 million in venture capital, plus $63.3 million in federal government grants. (They are in the midst of closing another round of funding, touted at $150 million.)

Loading

On New Zealand’s north coast, Rocket Lab has built a thriving orbital launch business behind its Electron rocket. But the thinnest of margins separate success from failure. In 2022, Gilmour was waiting on a $12 million tax rebate, and the payment was delayed. The company only had enough to pay the next few months’ expenses, so he thought he’d have to lay off half his staff. Then he heard that Sam Sicilia, chief investment officer for Hostplus, one of Australia’s largest superannuation funds, was on the Gold Coast. Gilmour raced over and offered Sicilia a tour of the rocket factory. The move worked, and the fund agreed to invest. “I went from despair to euphoria in five hours.”

Gilmour has few hobbies. Mostly, he builds rockets. When things are at their worst he retreats into what he can control. He was a good-enough young gymnast to dream of making the Olympics, and that’s how he stays fit. He’s working up to competition level again, and comes out of a session on the pommel-horse and roman rings spitting fury. “I bounce the other way, and get really fiery: I will do this,” he says. “I say the ‘f’ word to myself a lot.”

Once – if – they get to orbit, the next thing Gilmour needs to do is make money so the company is viable. His company has two competitors that dominate the top and bottom of the market. SpaceX’s $US70 million rockets can carry a weight of 22 tonnes to low Earth orbit, where 90 per cent of satellites circle. Rocket Lab’s tiny Electron can carry about 300 kilograms. Eris needs to hit somewhere in the middle – and for about $US8-9 million a trip. SpaceX has a two-year backlog for satellite launches, and can’t hit the range of different orbits Eris will theoretically be able to, so the opportunity is there.

“The market is so dysfunctional now, and the demand is so huge, all you need is a functional rocket and you will win,” says Gilmour. “I don’t need a special sauce. I just need a rocket that works.”

But he needs one before he runs out of money. “Businesses like this,” says a space industry insider, “they tend to go under.”

To stay operational, Gilmour Space has diversified. In June, it successfully launched a satellite (on a SpaceX rocket). They are also developing hypersonic launch vehicles which can reach speeds beyond Mach 5. The customers? Armed forces around the world at the moment are very interested in developing hypersonic missiles, which fly so fast that they are close to impossible to shoot down. The Royal Australian Air Force is trying to build its own hypersonic cruise missile. Gilmour’s service will allow Defence to test out materials, propulsion and guidance systems at extreme speeds. “We are not building hypersonic missiles with Defence,” Michelle tells me. The Gilmour Space mission statement is, in James’s words, “all orbits, all planets, for the benefit of humanity”.

Do hypersonic flight-test services for Defence meet that lofty ambition? Recall the story of the greatest rocketeer of all, Wernher von Braun, who led NASA to the moon – after cutting his teeth developing V-2 rockets for Nazi Germany. A rocket is a rocket, no matter what’s on top.

Loading

In Adam Gilmour’s dreams, the countdown rolls. At zero, Eris combines solid and liquid fuels and, with a spark, ignites them. Gas presses out of the thrusters and against the Earth, and pushes the vehicle upwards, slowly at first but then faster and faster. As Eris accelerates, she pushes harder and harder against the air, and the air pushes back, as though the atmosphere, upset at being punctured, is trying to crush the rocket. Eventually the rocket will reach maximum speed and pressure – a moment known as “max q”. This is the rocket’s greatest test. Fail and explode. Or succeed and punch through into clear, crisp space.

Gilmour is fast approaching his own max q. It’s been nearly a decade and more than $200 million since he pledged to launch a rocket into orbit. But spaceflight is like solving a billion little problems, one after another. Every day is painful. It’s very easy, tempting even, to believe he won’t make it – that Gilmour is little more than a gnat on Elon Musk’s shoulder.

But the Gilmours are used to not being believed. They think part of this is Australia’s cultural cringe: the belief we cannot do big things. Look at our risk-averse regulator, they say, or at all the poking-fun following their first launch.

Yet an absolute prerequisite of achieving the impossible is a belief that one can achieve the impossible. And you won’t find more fervent believers than Adam and James Gilmour. “It’s almost like a religious thing,” Gilmour says. James closes our chat with a raised fist: “To the stars.”

To read more from Good Weekend magazine, visit our page at The Sydney Morning Herald, The Age and Brisbane Times.